ArcelorMittal Asks Midrex to Design Demonstration Plant for Hydrogen Steel Production in Hamburg

17.09.2019

ArcelorMittal announced that it has commissioned technology provider Midrex Technologies to design a demonstration plant at its Hamburg site to produce steel with hydrogen. Both companies have now signed a Framework Collaboration Agreement to cooperate on several projects, ranging from research and development to the implementation of new technologies. The FCA will be governed by a number of Project Development Agreements, incorporating the expertise of Midrex and ArcelorMittal. The first Project Development Agreement is to demonstrate in Hamburg the large-scale production and use of Direct Reduced Iron (DRI) made with 100% hydrogen as the reductant.

In the coming years, the demonstration plant will produce about 100,000 tons of direct reduced iron per year - initially with grey hydrogen sourced from natural gas. Conversion to green hydrogen from renewable energy sources will take place once available in sufficient quantities and at an economical cost. Energy for hydrogen production could come from wind farms off the coast of Northern Germany. The plant will be the world’s first direct reduction plant on an industrial scale, powered by hydrogen.

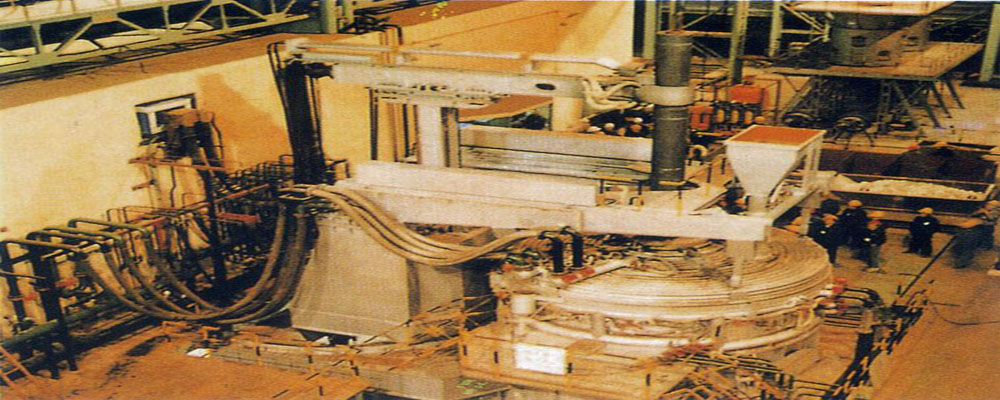

ArcelorMittal Hamburg already produces steel using DRI technology. During the process, iron oxide pellets are reduced to metallic iron, the raw material for high quality steel, by extracting oxygen using natural gas.